Dear Anti-Impact resin users, the Anti-Impact resin batch from June 5th has been upgraded to prevent component precipitation, and the exposure time in the printing setting needs to be increased by 14% compared with the old version, please note the date of manufacture on the label, thank you for your support

Anti-impact resin is a durable Nylon-like resin with high impact toughness and tensile toughness. The prints have low water absorption, high dimensional accuracy, and fine and wear-resistant surface. In addition, its mechanical properties are stable for a long time, with good fatigue resistance and weather resistance. It is suitable for printing repeatable machined, wet or underwater operation, impact resistant, snap on or movable parts, and even end use products.

▌ Attention

Anti-impact resin liquid has the characteristic smell of acrylate, which is quite pungent. It is recommended to use it in a ventilated environment or on a 3d printer with an air purifier.

Anti-impact liquid viscosity is relatively high (25 ℃/77 ℉, 700mpa. s), and the stiffness of thin wall or thin diameter structure is not enough, so the printing difficulty is higher than that of standard/rigid resin. When the ambient temperature is lower than 28 ℃/82.4 ℉, it is recommended to heat the resin liquid (80 ℃/176 ℉ water bath, 5-10 minutes) before printing, and increase the “Bottom lift distance”、“lifting distance” and “rest time after retract” in the slicer.

Prints will become soft and weak under the following conditions: liquids are stored unsealed after long-term exposure to air (especially in the environment with high humidity); Clean with solvent or ultrasonic for more than 5 minutes. The solution when the prints becomes soft is to place them in thermostatic drying oven at 60-80 ℃ (140-176 ℉) for 30 minutes before post curing. The prints will become harder and more stable.

▌ Features

High impact strength and tensile toughness

The prints can absorb energy well without being damaged under high-speed impact. The elongation at break (81-100%) and fracture stress are very high. The impact toughness and tensile toughness are both good and the toughness can be maintained for a long time. It is an ideal material for printing high toughness impact resistant parts.

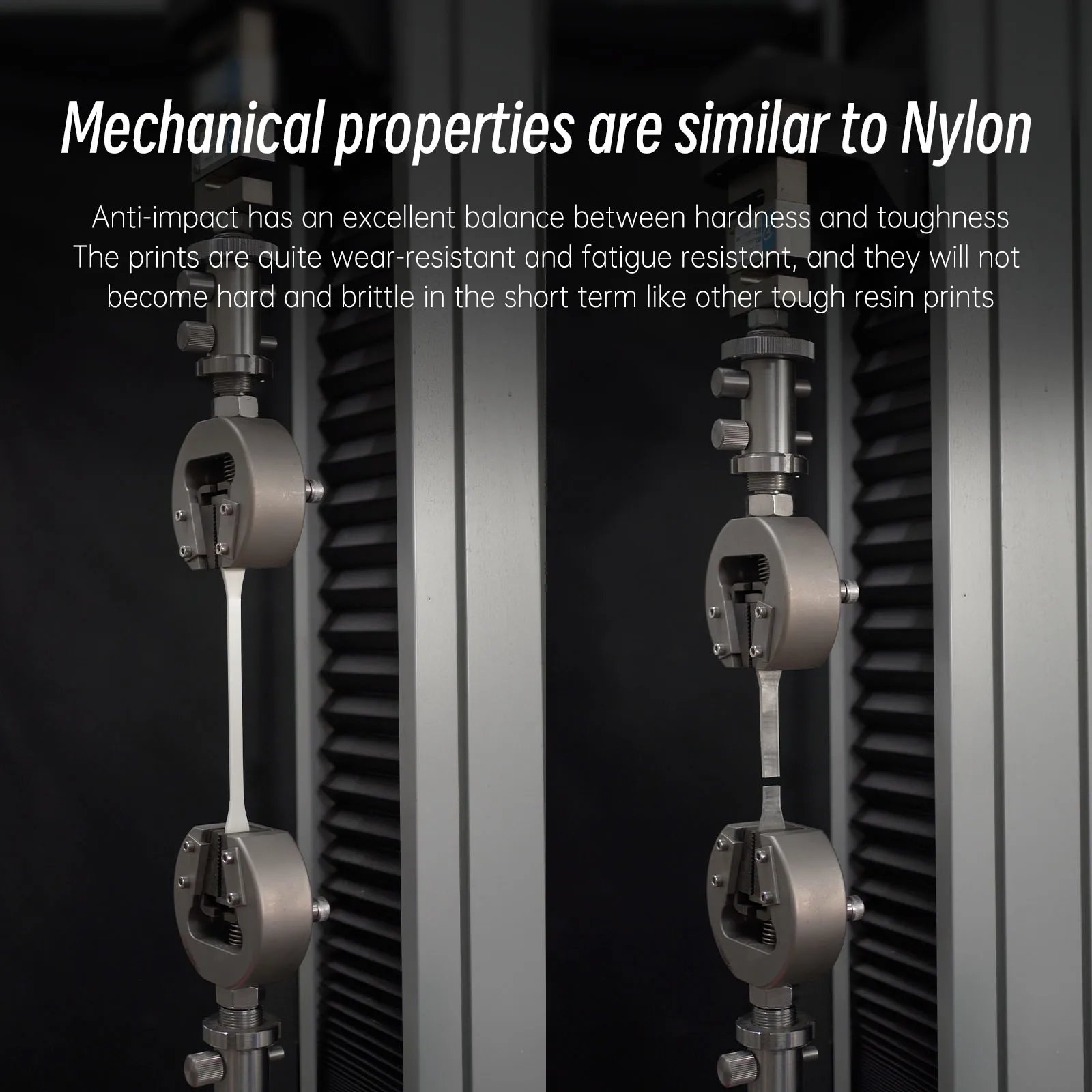

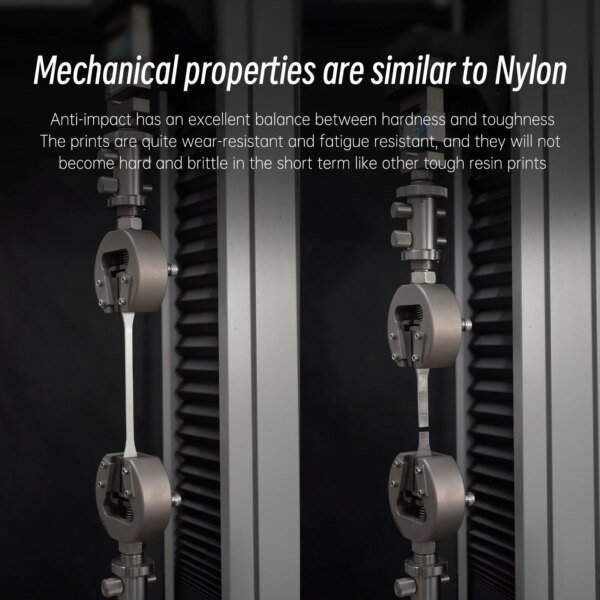

Mechanical properties are similar to nylon and stable for a long time

Anti-impact has an excellent balance between hardness and toughness. The prints are quite wear-resistant and fatigue resistant, the mechanical properties are similar to that of thermoplastic material–nylon. In addition, Anti-impacts prints will not become hard and brittle in the short term like other tough resin prints, their mechanical properties are stable in the long term, they are suitable for printing repeatable machined, impact resistant, snap on or movable parts, or even end use products.

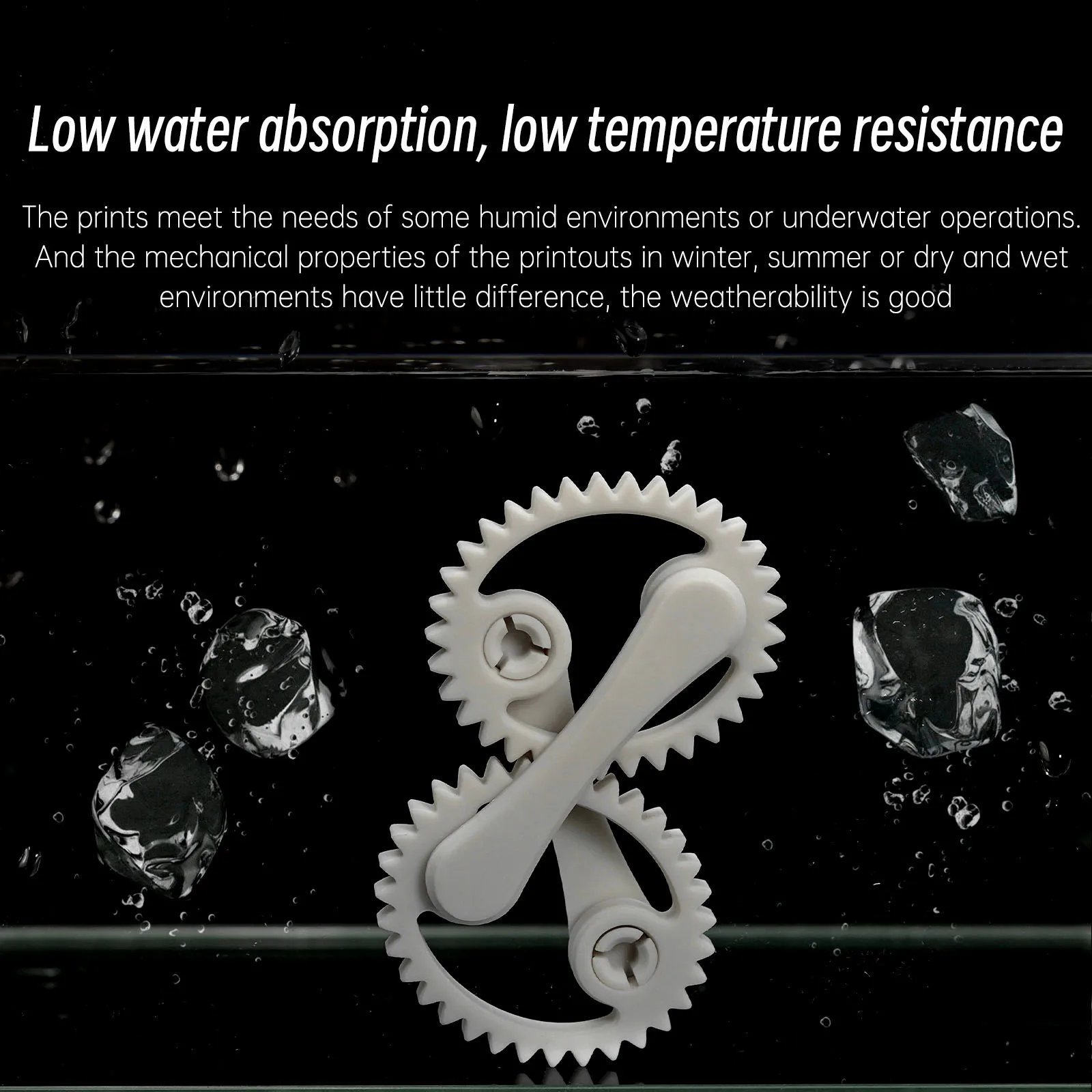

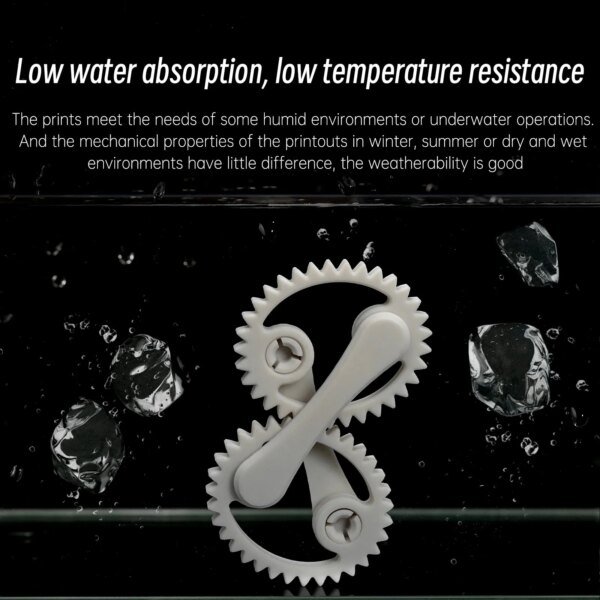

Low water absorption, low temperature resistance, good weatherability

The water absorption is as low as 0.46%, which can meet the needs of some humid environments or underwater operations. In addition, the mechanical properties of the printouts in winter, summer or dry and wet environments have little difference, the weatherability is good.

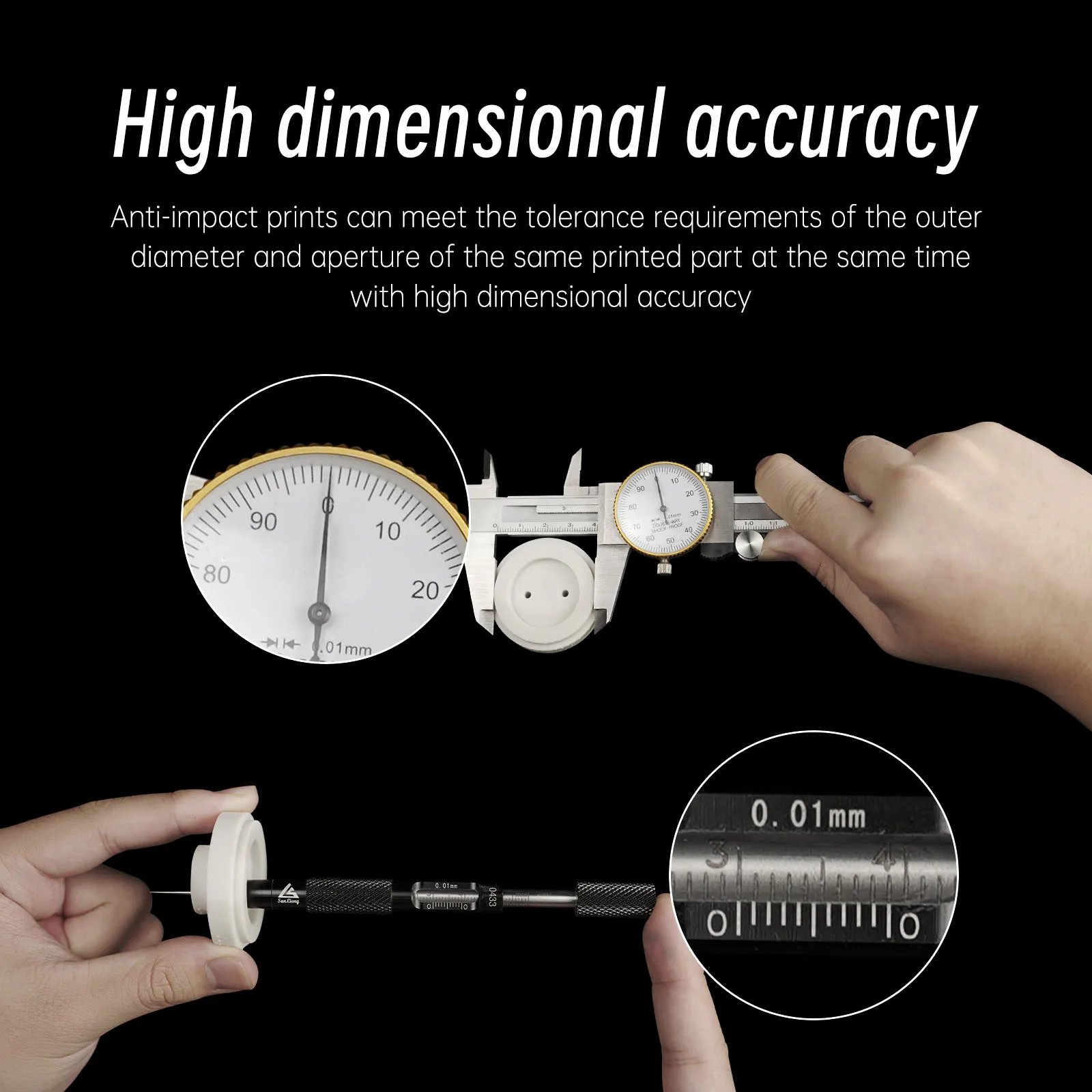

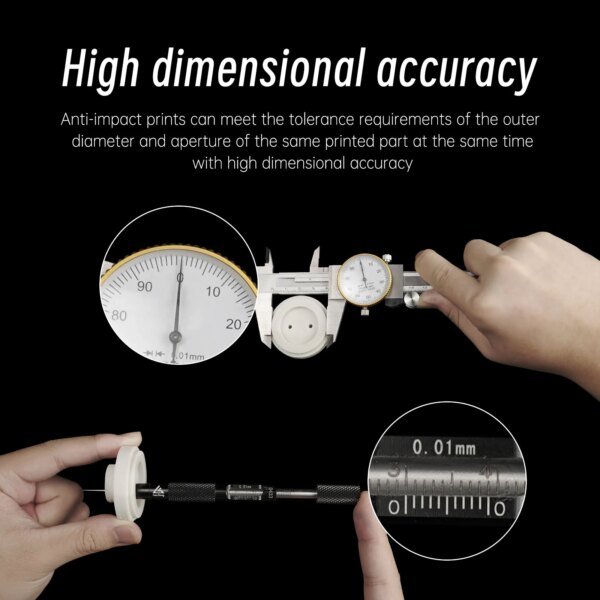

High dimensional accuracy, fine and wear-resistant surface

Anti-impact prints can meet the tolerance requirements of the outer diameter and aperture of the same printed part at the same time, with high dimensional accuracy. And the special formula makes the printing surface smooth and delicate, wear-resistant and scratch resistant.

Special smell, and not suitable for novices

Anti-impact resin liquid has the characteristic smell of acrylate, which is quite pungent. Anti-impact liquid viscosity is relatively high (25 ℃/77 ℉, 700mpa. s), and the stiffness of thin wall or thin diameter structure is not enough, so the printing difficulty is higher than that of standard/rigid resin. When the ambient temperature is lower than 28 ℃/82.4 ℉, it is recommended to heat the resin liquid (80 ℃/176 ℉ water bath, 5-10 minutes) before printing, and increase the “Bottom lift distance”、“lifting distance” and “rest time after retract” in the slicer

▌ Cleaning and Post-curing

Cleaning tools: Manual cleaning or Ultrasonic cleaner or 2 in 1 Wash Cure Machine

Cleaning time: 3mins

Cleaning solvent: 95% Ethanol or IPA

Post-curing light source: 385-405nm UV(40W)

Post-curing time: 30-60mins

Reviews

There are no reviews yet.