K+ has undergone a formula upgrade based on K resin, making it an ideal material for producing functional parts or assemblies. K+ and K printed parts have similar physical properties—High stiffness and toughness, extremely high dimensional and detail accuracy. However, K+ has lower water absorption and better scratch resistance compared to K, which makes K+ more widely used, such as for parts operating in high humidity environments or components that require repeated disassembly and assembly. In addition, the K+ printed parts are pure black and will not appear blue purple in sunlight, with a texture and mechanical properties similar to those of injection molded parts.

▌ Attention

K+ resin liquid has a special odor

Excessive post-curing or low temperature will make prints brittle

Do not apply too much force to the prints just after post-curing, it will take several hours for the prints to reach the mechanical properties they should have

▌ The difference between K+and K

K+ resin has some special odors compared to K

The K+ prints are pure black, while the K prints will show a deep blue purple color in sunlight

The water absorption of K+ printed parts is lower than that of K

K+ is scratch resistant, while K is not scratch resistant

▌ Descriptions

Stiff and Tough, High Strength

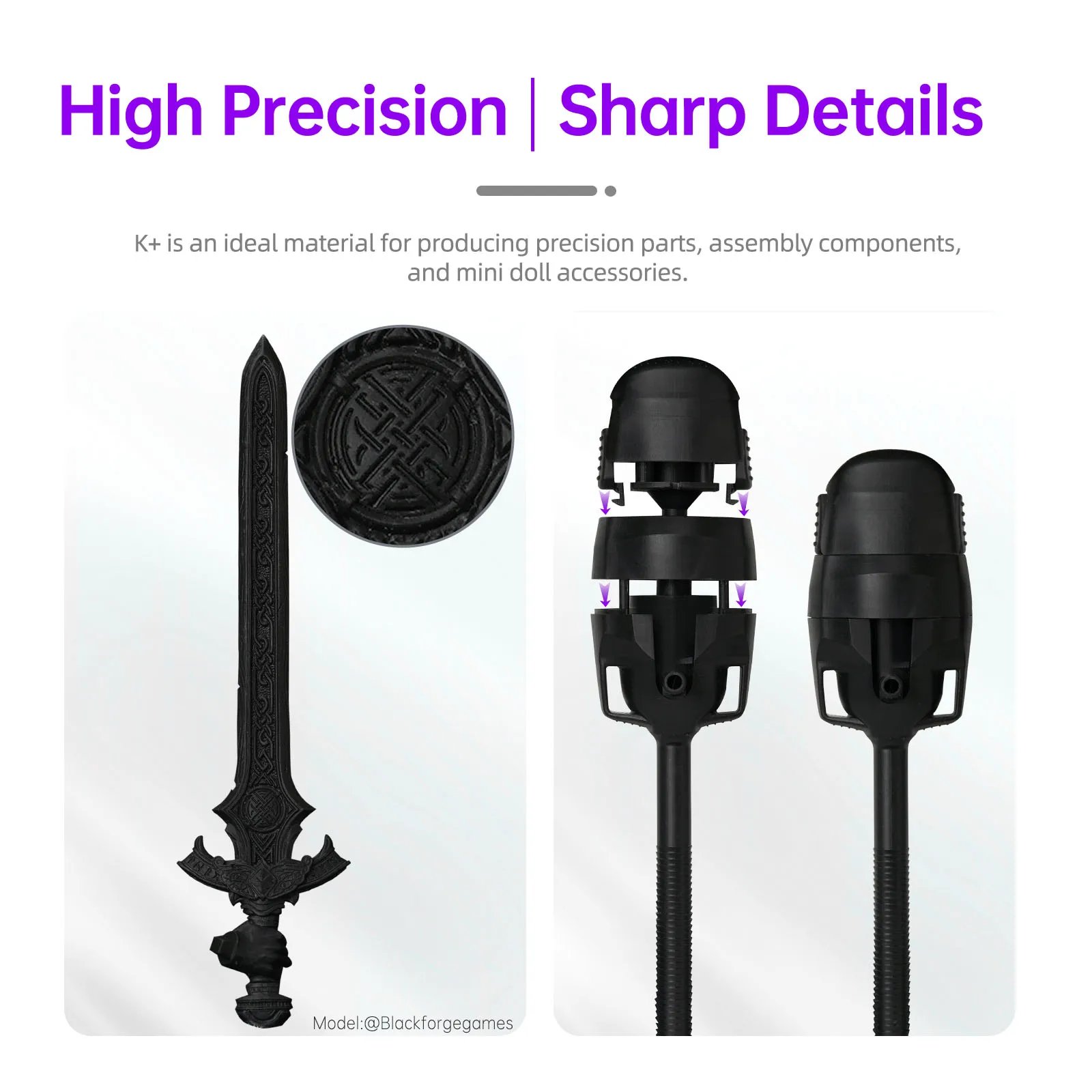

High Precision, Sharp Details

Low Water Absorption Printed Parts

Scratch Resistance

Pure black, with a texture similar to that of injection molded parts

▌ Print Settings

Operating Temp: 20~35℃/68~95℉

Layer Height: 0.05mm

Exposure Time: 3.3~5s

Bottom Exposure Time: 50~70s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥9mm

Rest Time After Retract/Off times /Light-off Delay: ≥2s

“Anti-aliasing”/”Grayscale” remains OFF!

▌ Cleaning and Post-curing

Cleaning time: ≤5mins

Cleaning solvent: 95% Ethanol or IPA

Post-curing light source: 385-405nm UV(40W)

Post-curing time: 10min

▌ Compatible 3D Printer

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

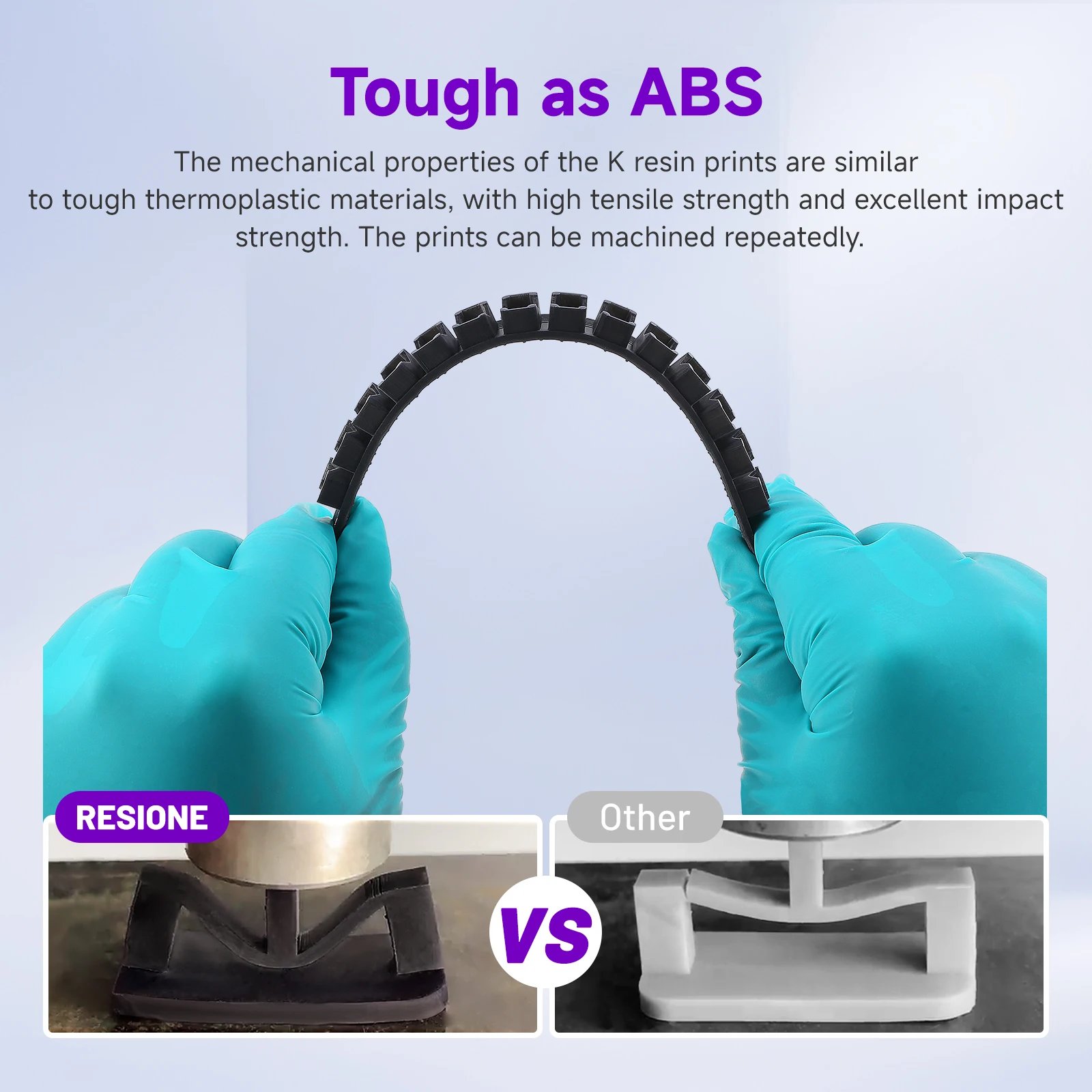

K resin is known for its excellent toughness and rigidity. This black material is not prone to overexposure under strong light sources, ensuring accurate size and sharp details. The mechanical properties of the printed parts are comparable to tough thermoplastics, allowing holes to be drilled, screws to inserted, and other high stress modifications, making it ideal for producing functional parts that will experience long term static load, transient stress or strain, but it is not suitable for underwater applications.

▌ Descriptions

All series of Anycubic,Elegoo,Nova3d,Peopoly,PhrozTough resin K/M58/M68/G217 can be mixed with F69/F39/F39T resin, which can make the printed parts tougher, more durable, and not brittle for a long timeen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

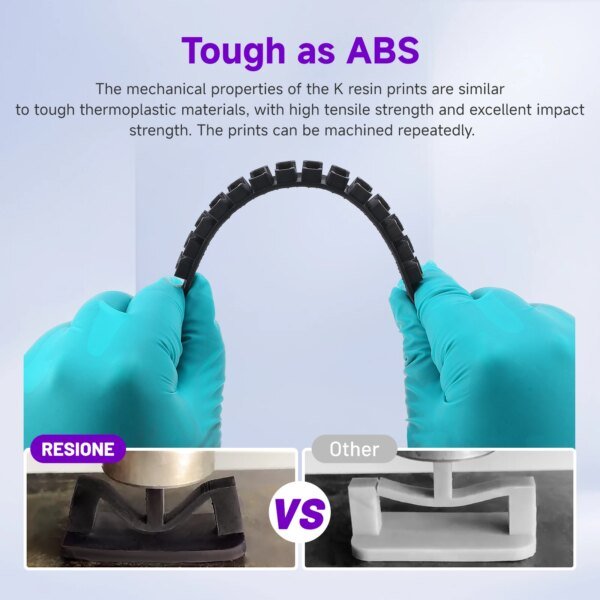

Good toughness and rigidity

The mechanical properties of the K resin prints are similar to tough thermoplastic materials, with high tensile strength and excellent impact strength. The prints can be machined repeatedly

Precise size and sharp details

This material is not easy to overexpose even under strong light source, the printed parts are accurate in size. Any 3d data can be accurately restored

Black color is high in saturation

The black color is high in saturation, which makes prints have a good texture, and it looks more like an injection molded product after polishing

High-quality raw materials

RESlONE prioritizes user care over cost considerations, selecting high-purity, low-irritation premium raw materials from around the world

▌ Applications

Functional parts

Snap-fit designs

Jigs and fixtures

Assembly parts

Protective shell

Miniatures

Toy figures

▌ The difference between M58, M68 and K

Color:M58 is light gray, M68 is white, K is black

Toughness: K ≥ M68>M58;Rigidity: K ≤ M68<M58

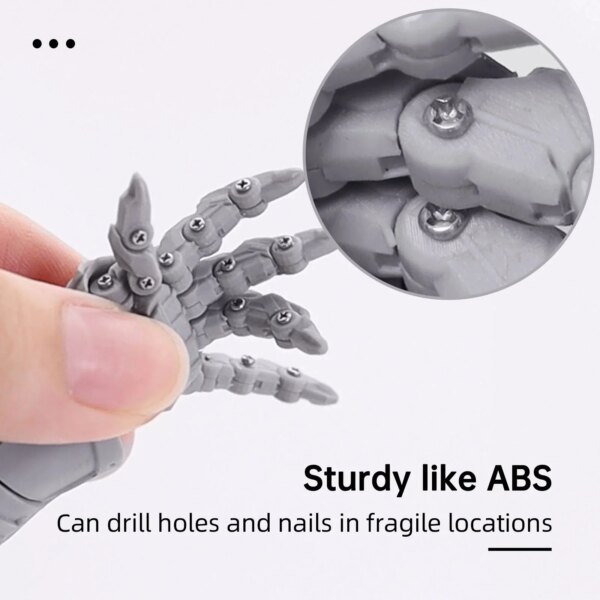

M58 is a gray material known for its rigidity and toughness. The mechanical properties of the printed parts are comparable to tough thermoplastics, allowing holes to be drilled, screws to inserted, and other high stress modifications, making it ideal for producing functional parts that will experience long term static load, transient stress or strain, but it is not suitable for underwater applications. This 3D printer resin boasts high molding precision, wear resistance, and a smooth surface that preserves fine details from the original 3D file, so it’s also well-suited for producing miniatures and action figures.

Sturdy like ABS

The mechanical properties of the M58 resin printed parts are similar to tough thermoplastic materials, with high tensile strength and excellent impact strength, can drill holes and nails in fragile locations.

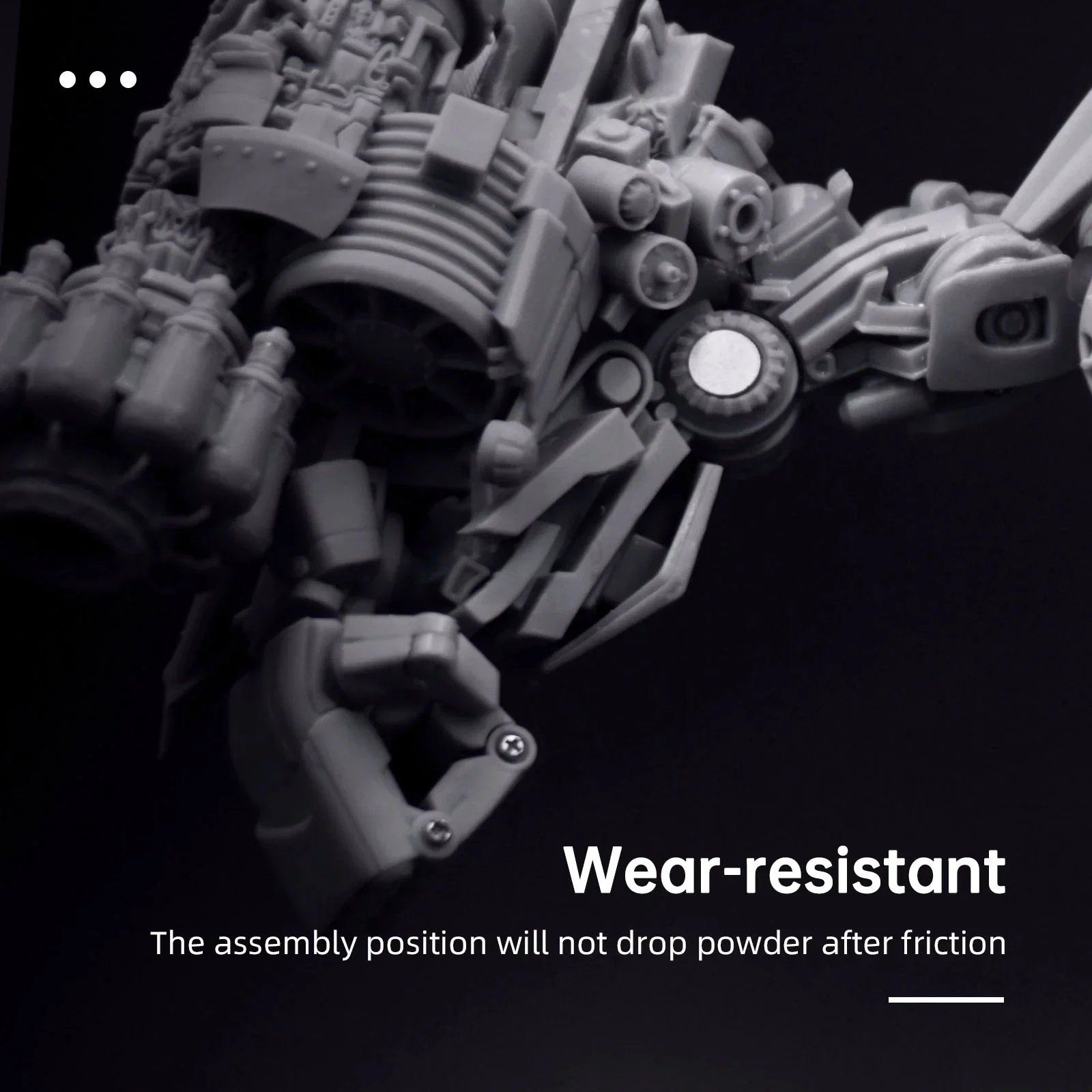

Wear-resistant and scratch-resistant

The surface of M58 resin print is very hard, the assembly position will not drop powder after friction, suitable for printing movable joints, gears or bearing parts.

Clear and sharp details

M58 resin has high molding accuracy, is not easy to overexpose, and can accurately restore the fine details in 3d files.

▌ Applications

Action figures

Miniatures

GK

Functional parts

Assembly parts

Jigs and fixtures

Snap-fit designs

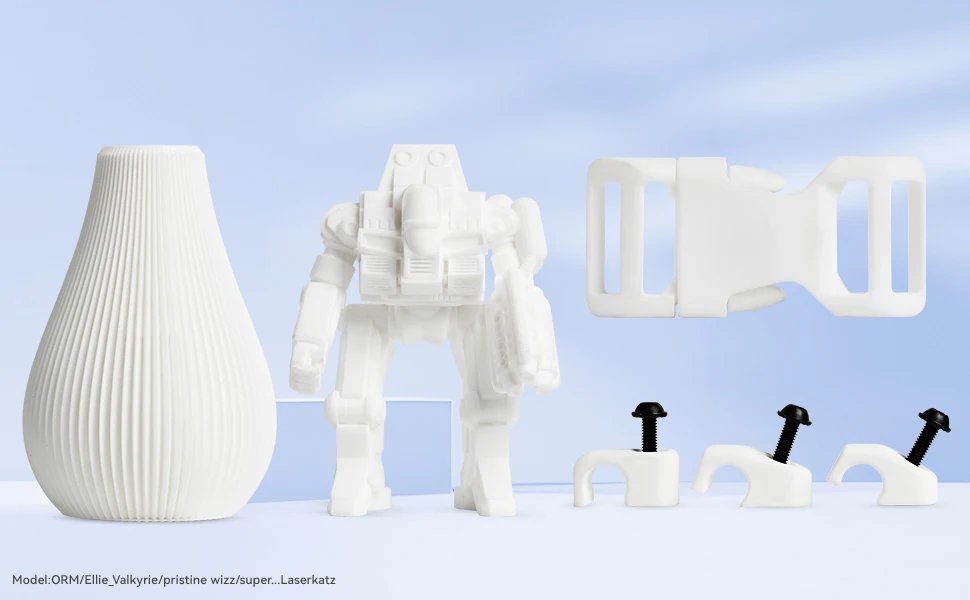

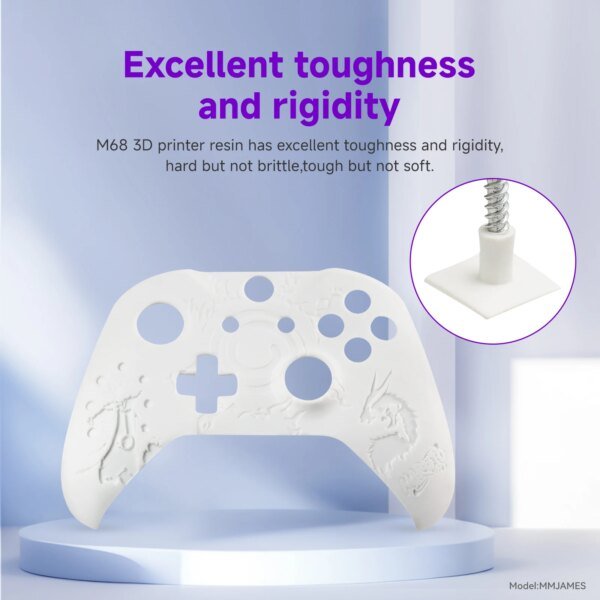

M68 is known for its rigidity and toughness, and it is a white and non-yellowing material. The mechanical properties of the printed parts are comparable to tough thermoplastics, allowing holes to be drilled, screws to inserted, and other high stress modifications, making it ideal for producing functional parts that will experience long term static load, transient stress or strain, but it is not suitable for underwater applications. Additionally, it is deeply loved by artists, toy producers, architects, 3D printing service providers, and others due to its beautiful pure white appearance.

Excellent toughness and rigidity

M68 3D printer resin has excellent toughness and rigidity, hard but not brittle, tough but not soft.

Non-yellowing

The color of M68 3d resin is pure white, and it will not turn yellow under long-term storage under indoor conditions, which is very suitable for 3d printing artworks or decorations.

High-quality raw materials

RESlONE prioritizes user care over cost considerations, selecting high-purity, low-irritation premium raw materials from around the world.

Wide adaptability

Designed for 385~405nm UV LED light source, it is suitable for mainstream LCD/MSLA/DLP resin 3D printers on the market.

▌ Applications

Figure toys

Action figures

Protective shells

Functional parts

Art works

Architectural models

Assembly parts

Jigs and fixtures

Snap-fit designs

Reviews

There are no reviews yet.