ANYCUBIC PLA Silk Dual-Color or Tri-Color filament

Silk Appearance and Shine Bright | Complete Compatibility| Adhesion at lts Finest

Silk-Like Appearance Shining Glow

Adopted a cutting-edge triple dual-extrusion production process, the Anycubic PLA Slick Dual-Color filament combines two or three colors in the entire spool.Printed models come out with a silk-like texture and a gradient effect, radiating with luminous colors and captivating brilliance.

Complete Compatibility

The Anycubic PLA Silk Dual-Color filament offers great compatibility with a wide range of temperatures and printing speeds, making it suitable for mainstream printers available on the market. This versatility allows users to achieve optimal printing results regardless of their specific printer model.

Recommended printing temperature195-215C

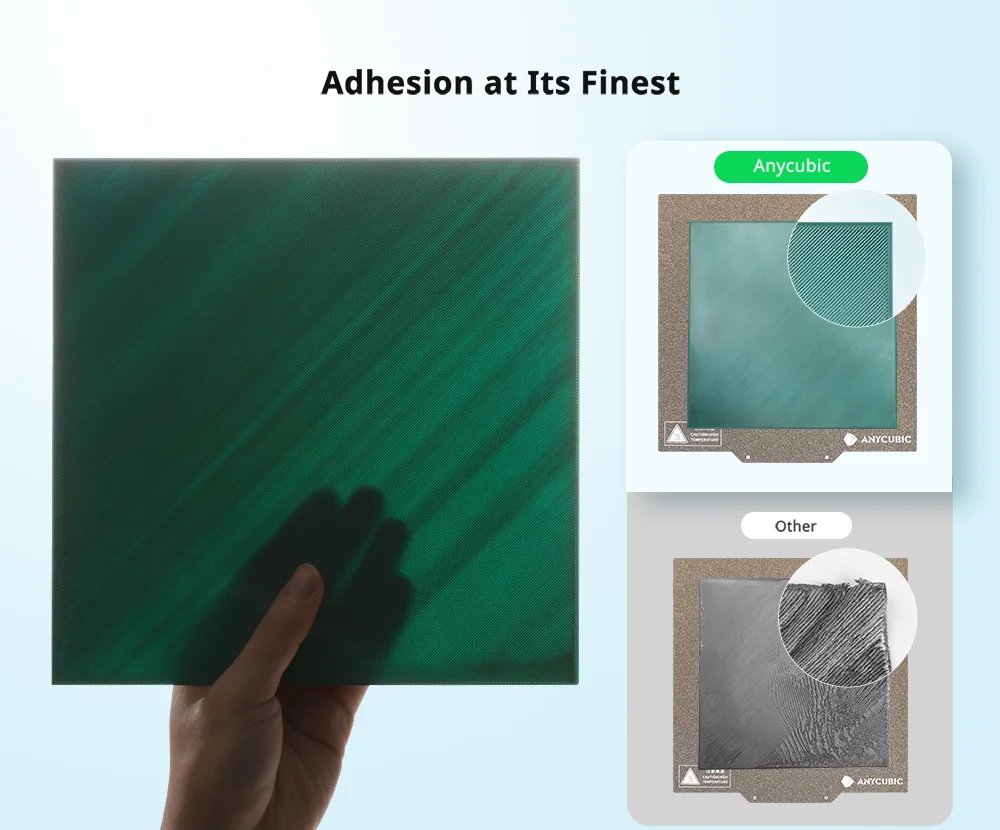

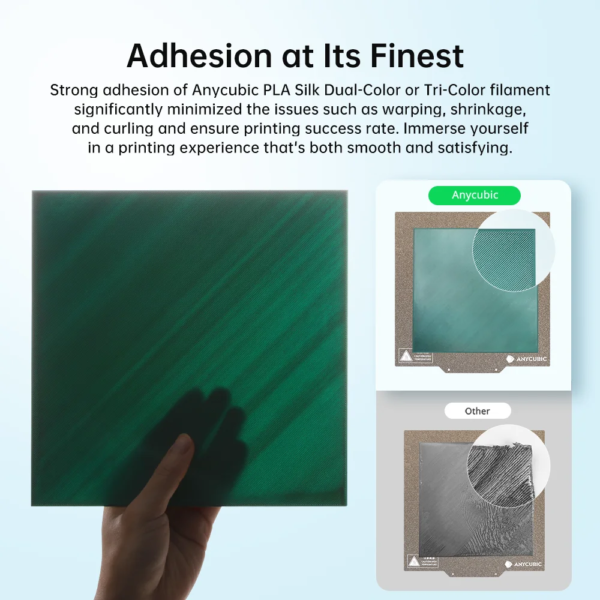

Adhesionat Its Finest

Strong adhesion of Anycubic PLA Silk Dual-Color filament significantly minimized the issues such as warping, shrinkage, and curling and ensure printing success rate. Immerse yourself in a printing experience that’s both smooth and satisfying.

Bye Bye Bubbles & Blockage

Reusable vacuum bags and sealed with desiccant protect the filament from moisture, and avoid bubbles or inconsistent flow during the printing process.

Evermore Eco-friendly

PLA is made from lactic acid, which is produced via starch fermentation during corn(or other plant) wet milling, it’s a biodegradable and eco-friendly material.

Available Colors

Products used in the pictures are real products,still theremay be color difference due to light or displav The color of the product received shall prevail.

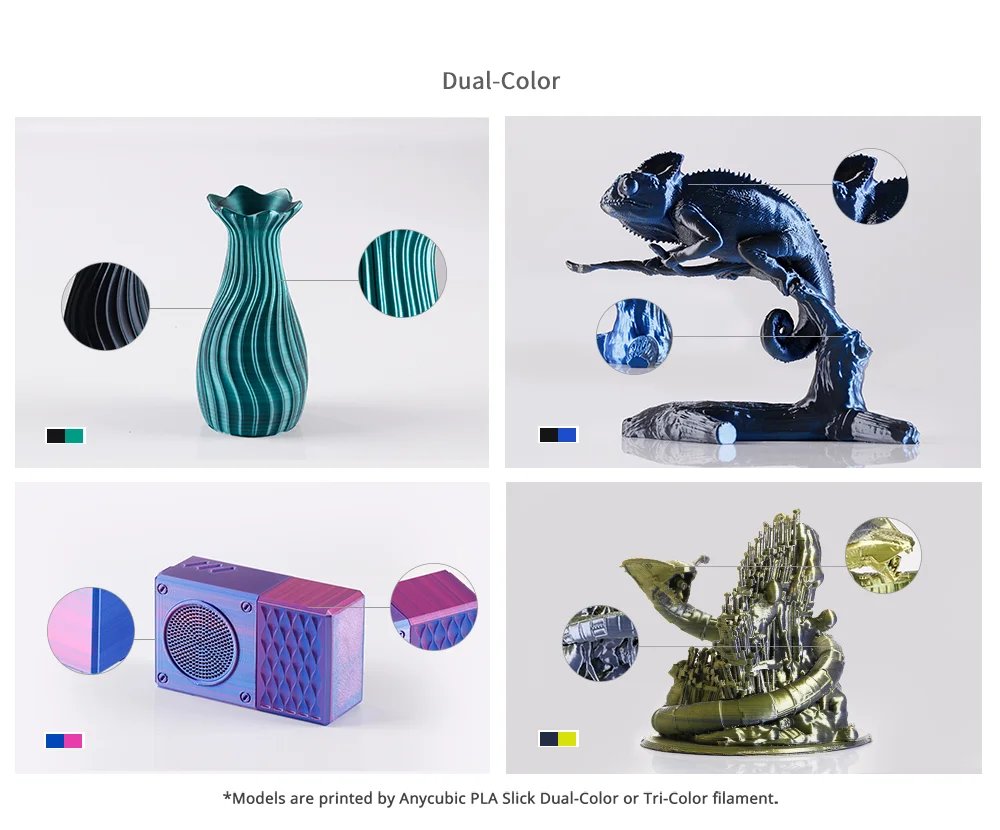

Model Demo

*Models are printed by Anycubic PLA Slick Dual-Color or Tri-Color filament.

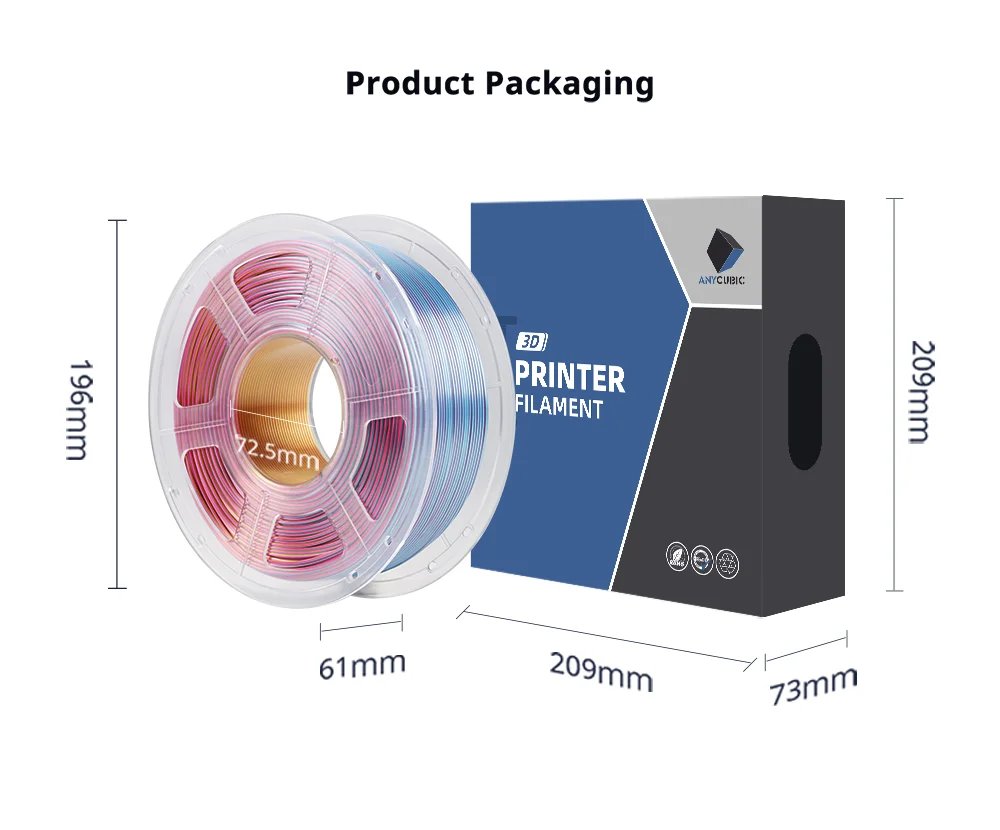

Product Parameters

Test items——Parameters

Product type——Anycubic PLA Slick Dual-Color or Tri-Color filament

Net Weight——1KG/Roll

Diameter——1.75mm

Tolerance——±0.05mm

Gross Weight——1.26KG

Density——1.25g/cm3

Length——330m

Tensile Strength——60.6MPa

Elongation at Break——6.3%

Flexural Strength——65MPa

Flexural Model——2400-2800MPa

Young’s Mode——2760MPa

lzod lmpact Strength——33KJ/m2

Melting Point——164°C

Melt Index——9g/10min

Heat Distortion Temperature——53℃

Storage Environment——Dry and ventilated

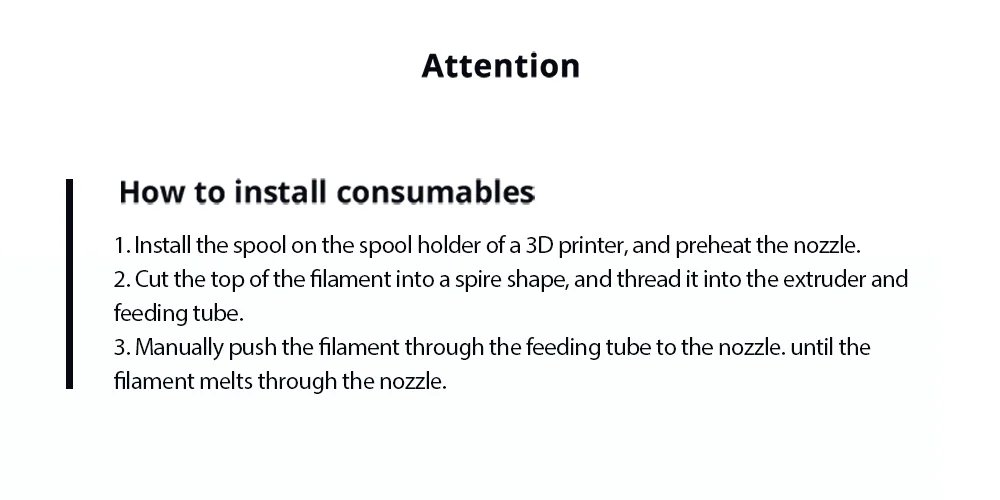

How to install consumables

1. Install the spool on the spool holder of a 3D printer, and preheatthe nozzle.

2. Cut the top of the filament into a spire shape, and thread it intothe extruder and feeding tube.

3. Manually push the filament through the feeding tube to the nozzle.until the filament melts through the nozzle.

Reviews

There are no reviews yet.