Anycubic High Speed Resin

Born to Be Fast

3X Faster Printing Speed | Low Viscosity | High Activity

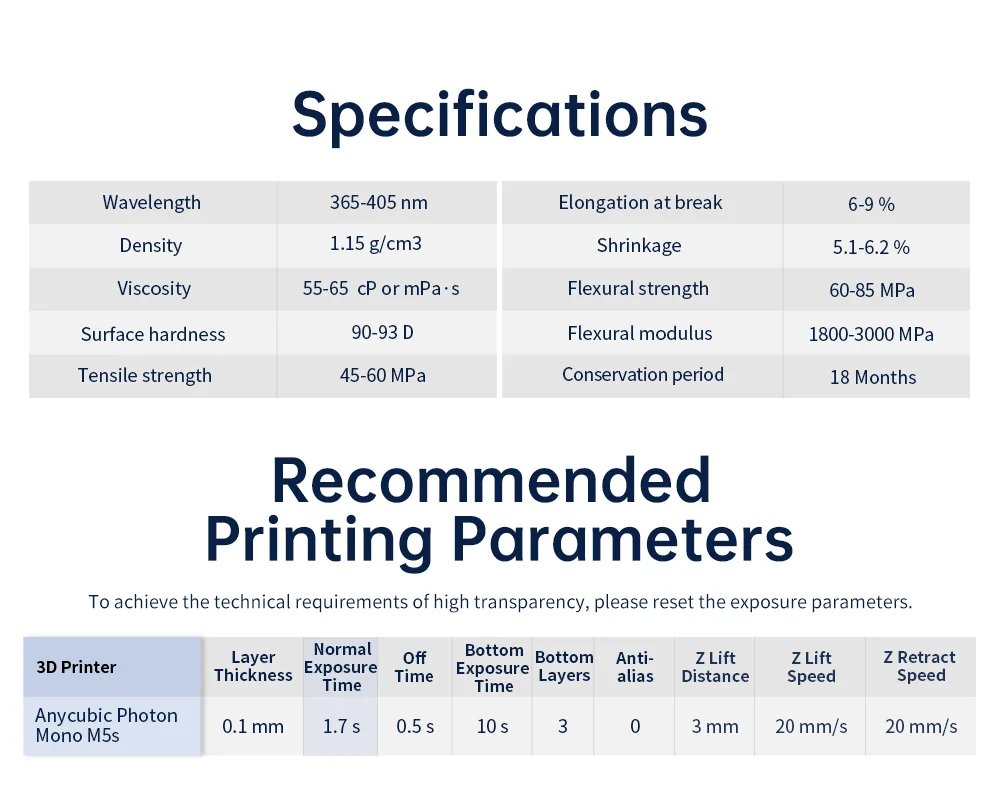

Specifications

Wavelength :365-405nm Elongation at break : 6-9%

Density: 1.15 g/cm3 Shrinkage : 5.1-6.2%

Viscosity: 55-65 cPormPa·s Flexural strength : 60-85 MPa

Surface hardness : 90-93 D Flexural modulus : 1800-3000 MPa

Tensile strength : 45-60 MPa Conservation period :12 Months

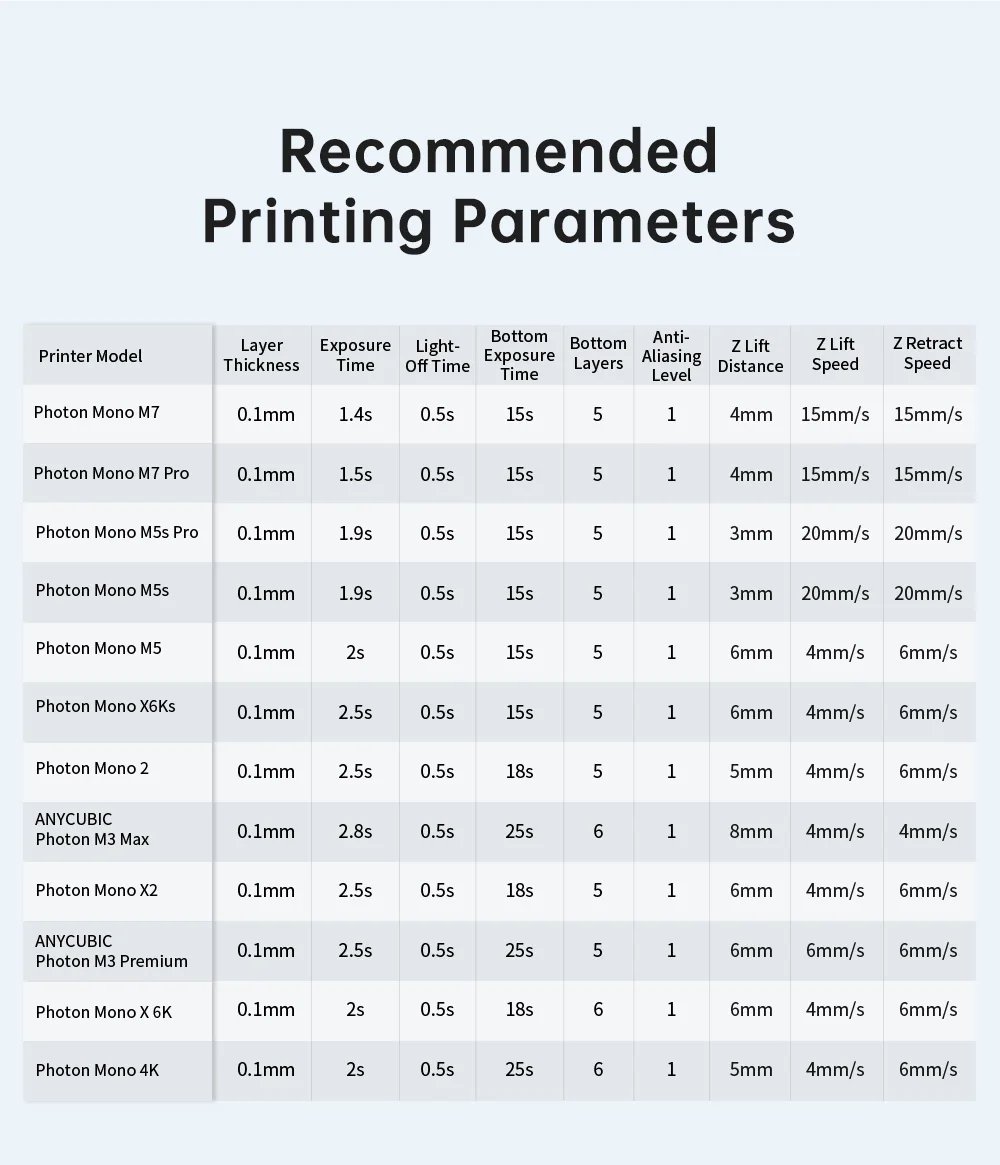

Recommended Printing Parameters

To achieve the technical requirements of high transparency, please reset the exposure parameters.

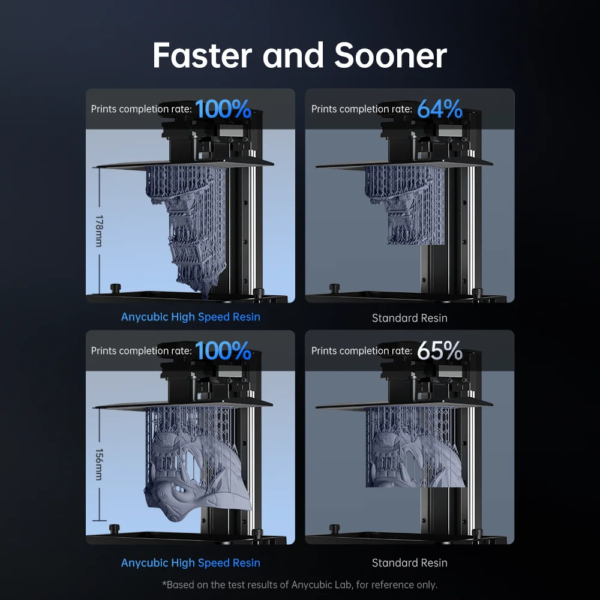

Print Up To 3X Faster

Specially developed for Anycubic Photon Mono M5s. Its low viscosity and high activity contributes to decreasing exposure and curing time, realizing a 3X faster printing experience.

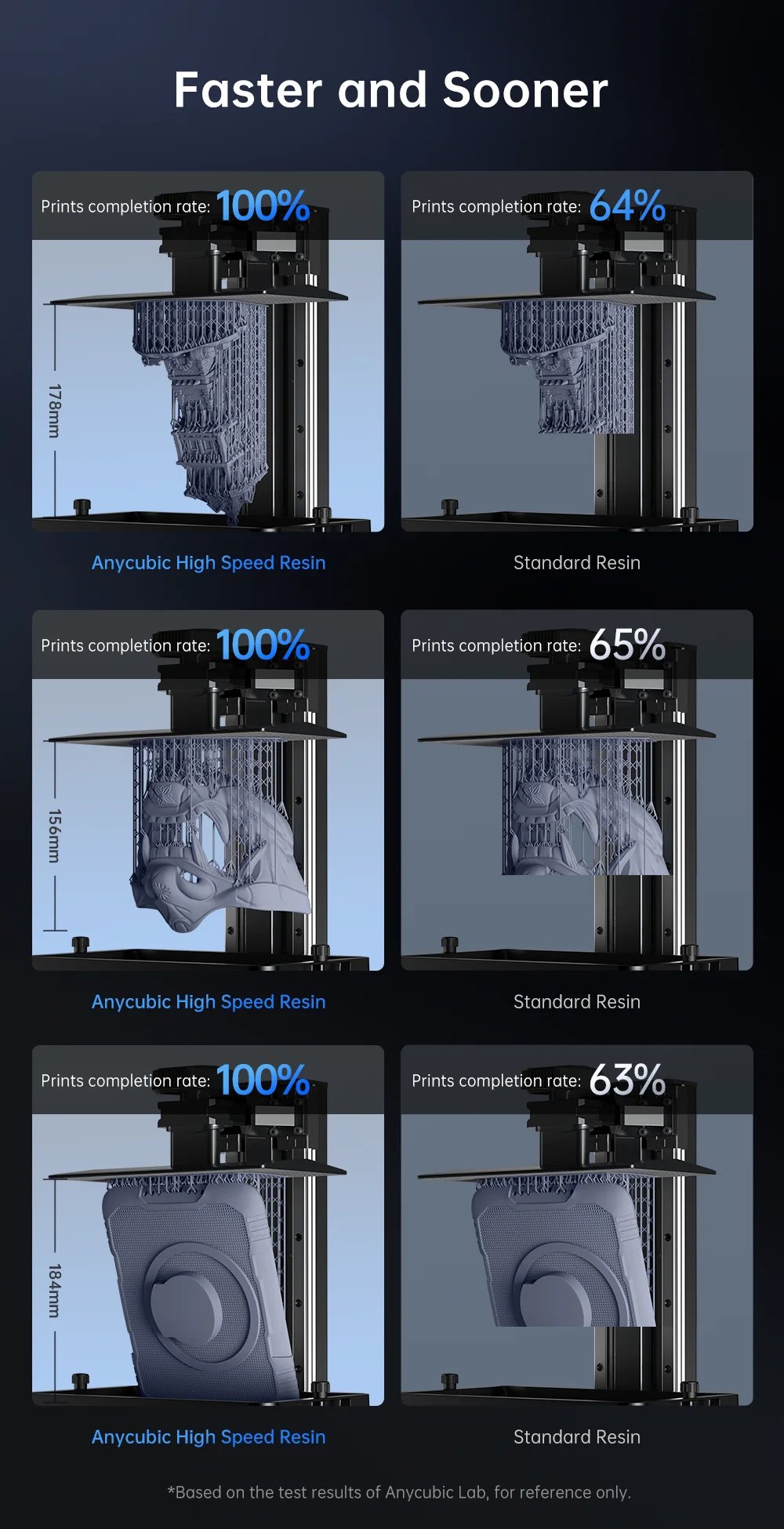

Faster and Sooner

Speedy and Stable

The low-viscosity feature enables it to take away heat through rapid flow when the platform is raised and lowered, preventing local overheating, and at the same time reflows quickly to ensure printing accuracy.

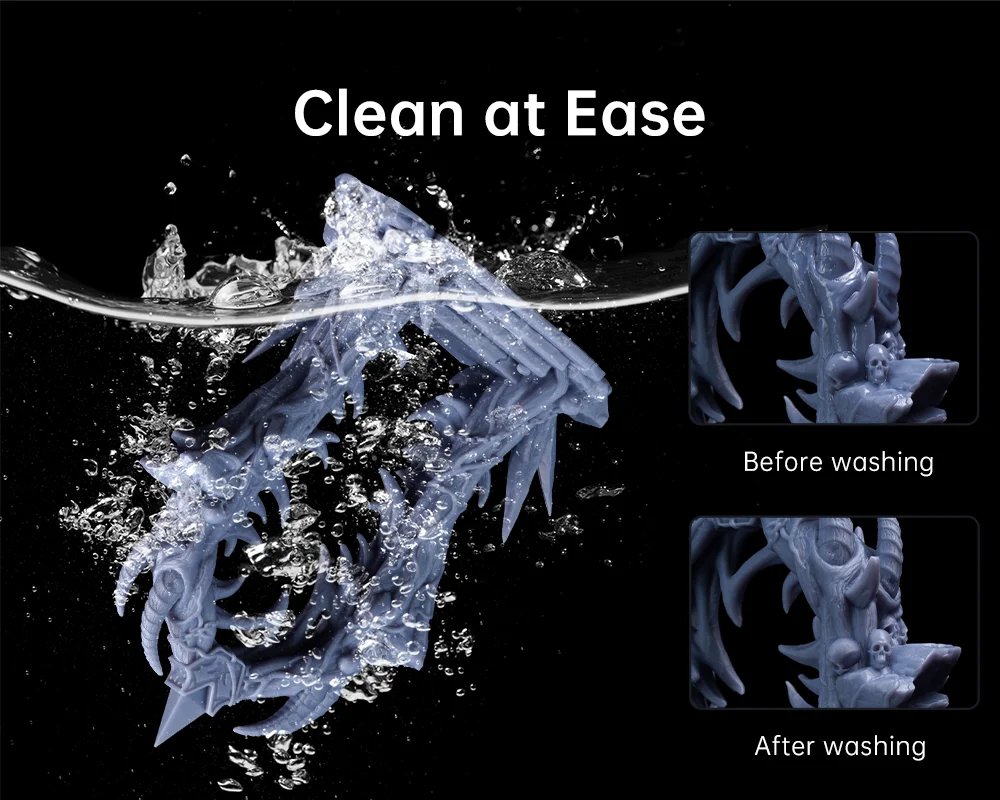

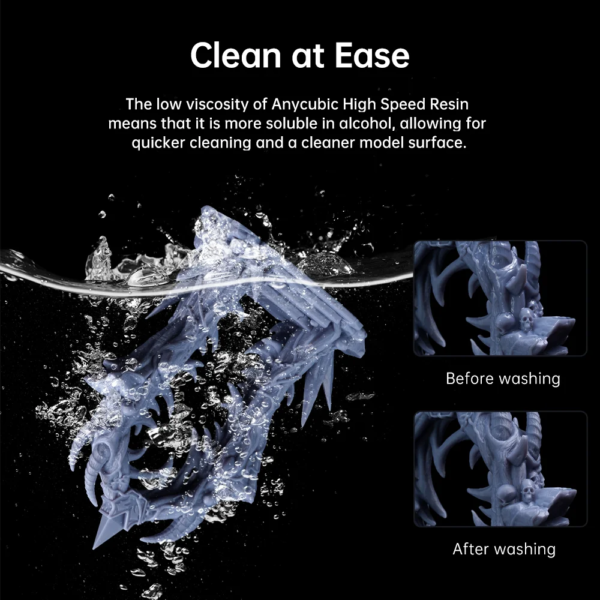

Clean at Ease

Reliable and Safe

The bottle is designed to be leak-proof, and the strict packaging process reduces the risk of damage during transportation.

Model Display

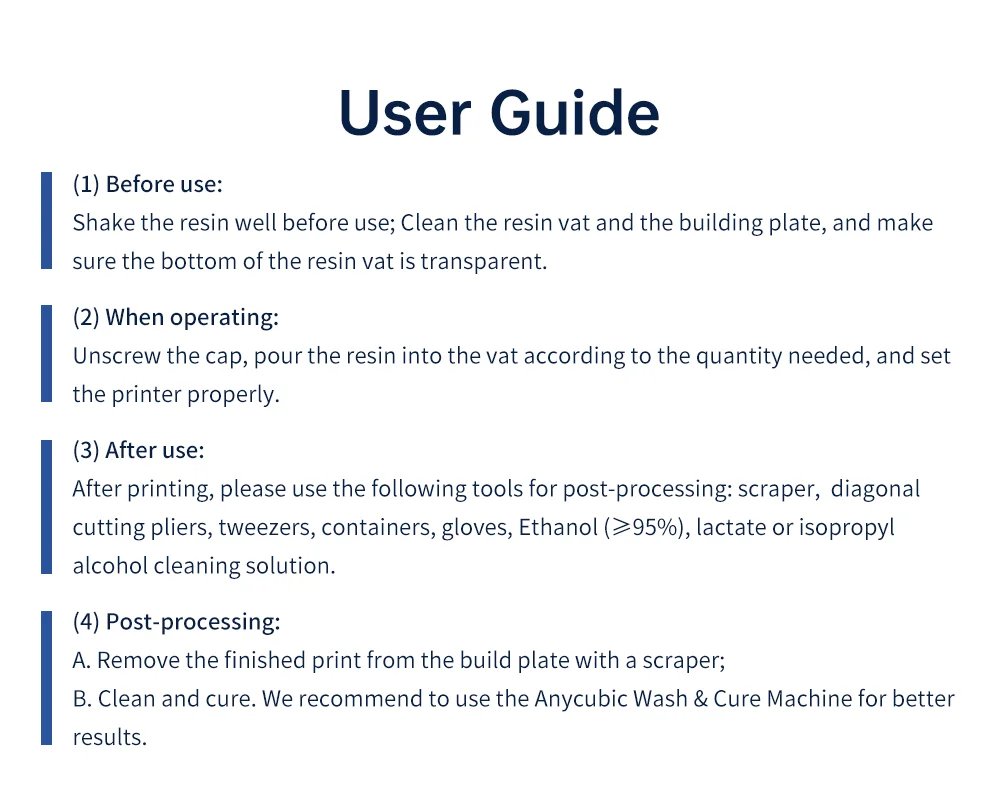

User Guide

(1) Before use:

Shake the resin well before use;

Clean the resin vat and the building plate, and make sure the bottom of the resin vat is transparent.

(2) When operating:

Unscrew the cap, pour the resin into the vat according to the quantity needed, and set the printer properly.

(3) After use:

After printing, please use the following tools for post processing: scraper, diagonal cutting pliers, tweezers, containers, gloves, Ethanol (≥95%), lactate or isopropyl alcohol cleaning solution.

(4) Post-processing:

A. Remove the finished print from the build plate with a scraper;

B. Clean and cure. We recommend to use the Anycubic Wash & Cure Machine for better results.

C. Remove supports, polish and paint, etc…

Precautions

1 Store at room temperature, keep sealed and away from light. Avoid heat and direct sunlight.

2 Suggested storage temperature: 18-35℃.

Lowtemperatures might affect the printing results. The resin can be preheated (no more than 60C) before use. In case ofresin pigment settlement, please stir or shake well before use.

3 To ensure the best properties of the cured models, remember to control

the intensity and the exposure time of the light source.

To ensure the ideal curing material performance, the post-curing light intensity and time need to be controlled as suggested:

(1) The intensity of lamps or LED light source should not exceed 5-10mW/cm² and the exposition time should not exceed 1 hour (self-regulation);

(2) Close range exposure or prolonged exposure under strong light sources such as high power and high voltage lamp is prohibited.

(3) It is recommended to print in a dark room or put on the cover when printing.

Material performance may vary and is subject to the machine used and

post-curing technique. Please refer to the product MSDS for safety information. If you have any problems or questions, please feel free to contact us.

Reviews

There are no reviews yet.