Tough74 resin is a wear-resistant, tough material with excellent surface quality, making it ideal for producing durable action figures. It offers good notched impact strength and elongation at break, while also maintaining impressive rigidity. The material has a smooth, wear-resistant surface. Movable dolls printed with Tough74 exhibit exquisite surface quality and playability comparable to traditionally manufactured products. The joints maintain tight engagement even with prolonged friction, and thin structures do not break unexpectedly during assembly or play.

▌ Attention

Please fully post-cure the parts at the joint engagement positions. Ensure that these parts are exposed to UV light without obstruction in the post-curing chamber to achieve the required wear resistance

If the post-curing time is too long, it can cause warping of the printed parts and make them hard and brittle

Immediately after post-curing, the printed parts is fragile. It is not recommended to apply force to the prints. It is advisable to wait for a period of time for the prints to cool naturally to release internal stresses and restore its intended mechanical properties

▌ Descriptions

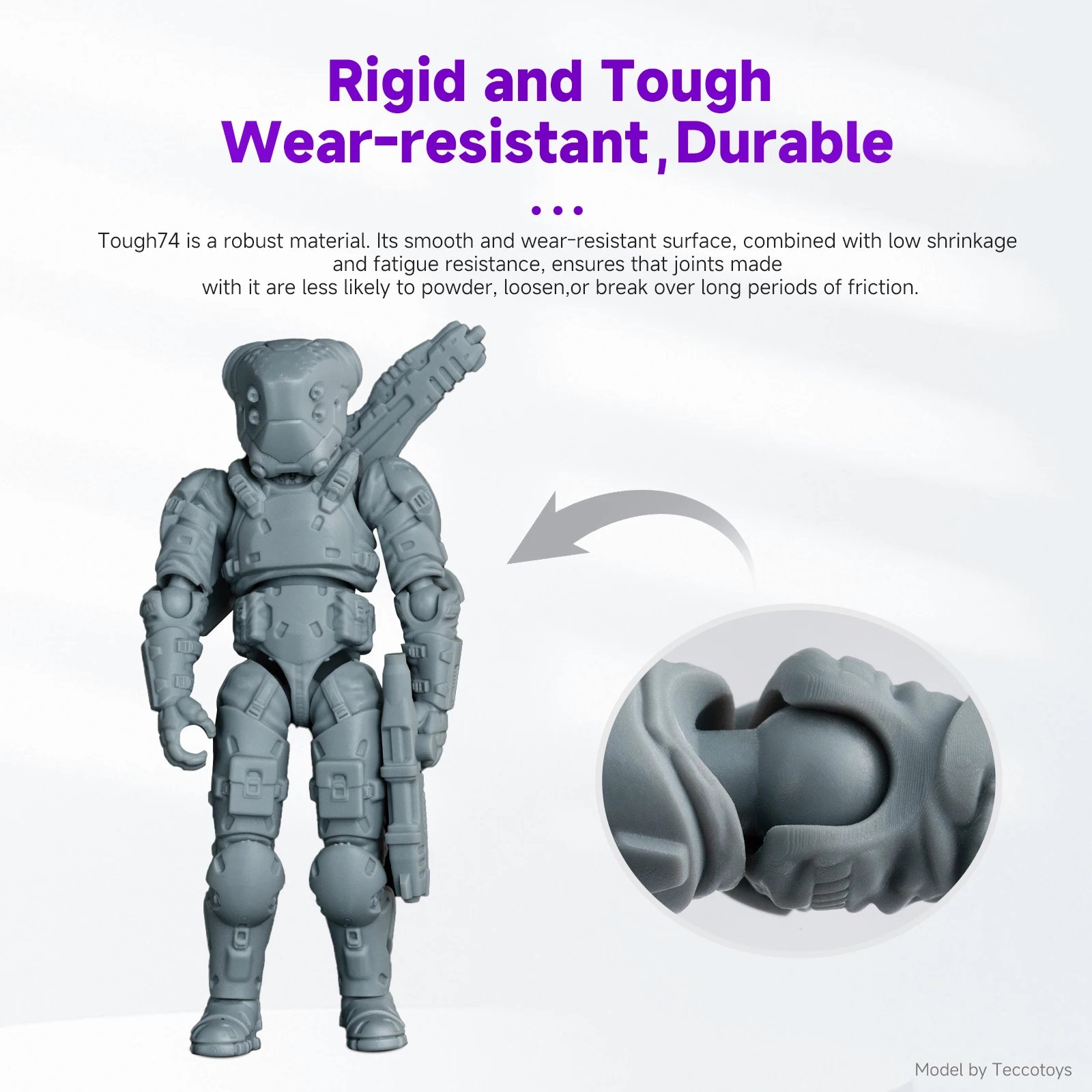

Rigid and Tough, Wear-resistant, Durable

RESIONE Tough74 is a robust material with excellent toughness indicators such as notch impact strength and elongation at break, as well as rigidity indicators like bending and tensile strength. Its smooth and wear-resistant surface, combined with low shrinkage and fatigue resistance, ensures that joints made with it are less likely to powder, loosen, or break over long periods of friction. We recommend presetting a size gap of about 0.05mm at the joint engagement positions during modeling.

Fine Surface, Easy to Clean

Tough74’s formula is specially designed to produce models with smooth surfaces without losing intricate details. Printed parts are easy to clean, and after washing, the surface is non-sticky and non-reflective, providing a texture comparable to traditionally manufactured products.

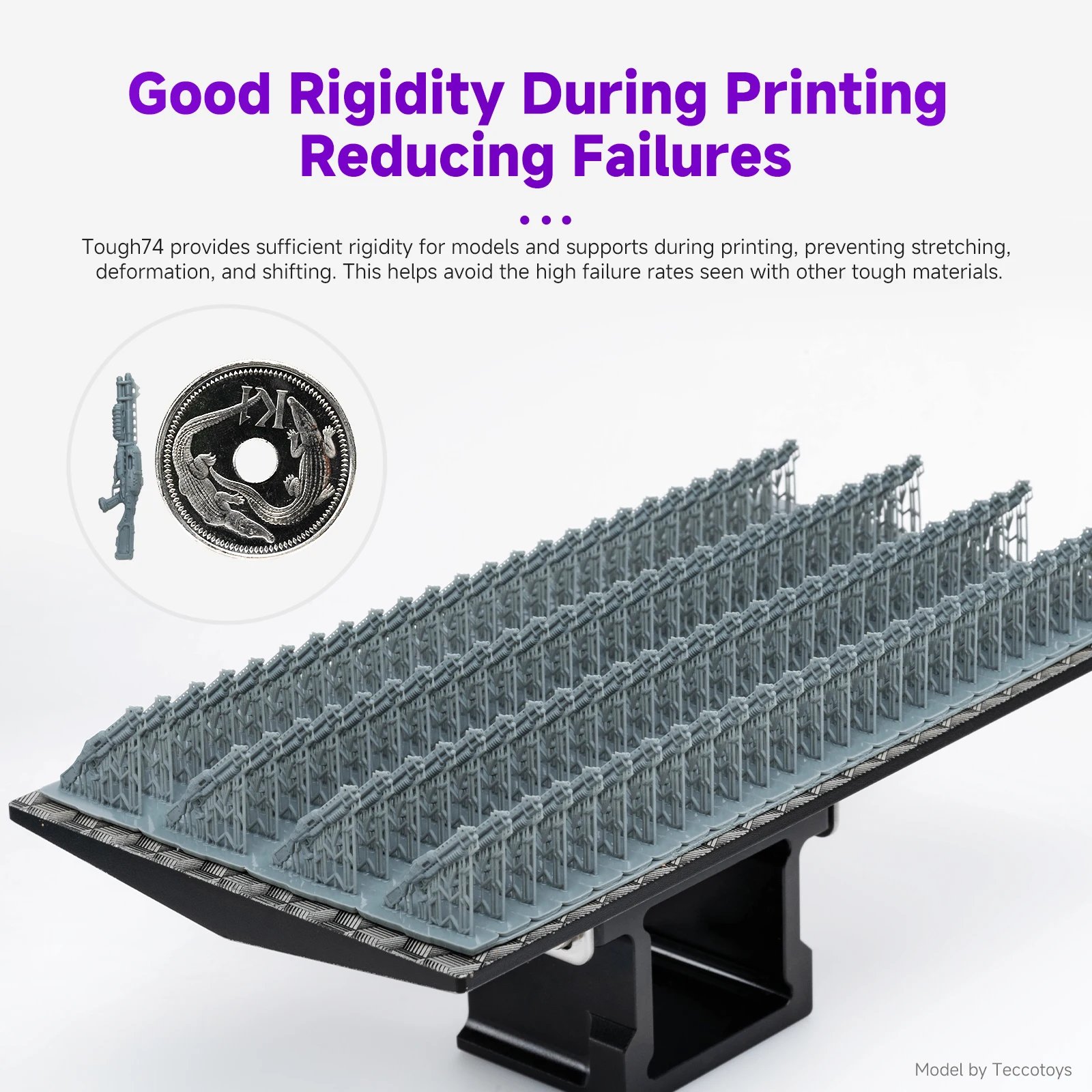

Good Rigidity During Printing, Reducing Failures

Tough74 combines rigidity and toughness, providing sufficient rigidity for models and supports during printing, preventing stretching, deformation, and shifting. This helps avoid the high failure rates seen with other tough materials. When printing lightweight models like miniatures and doll parts, this material allows for the addition of fine supports, reducing damage to the model, saving post-processing time, and delivering higher quality prints and production efficiency.

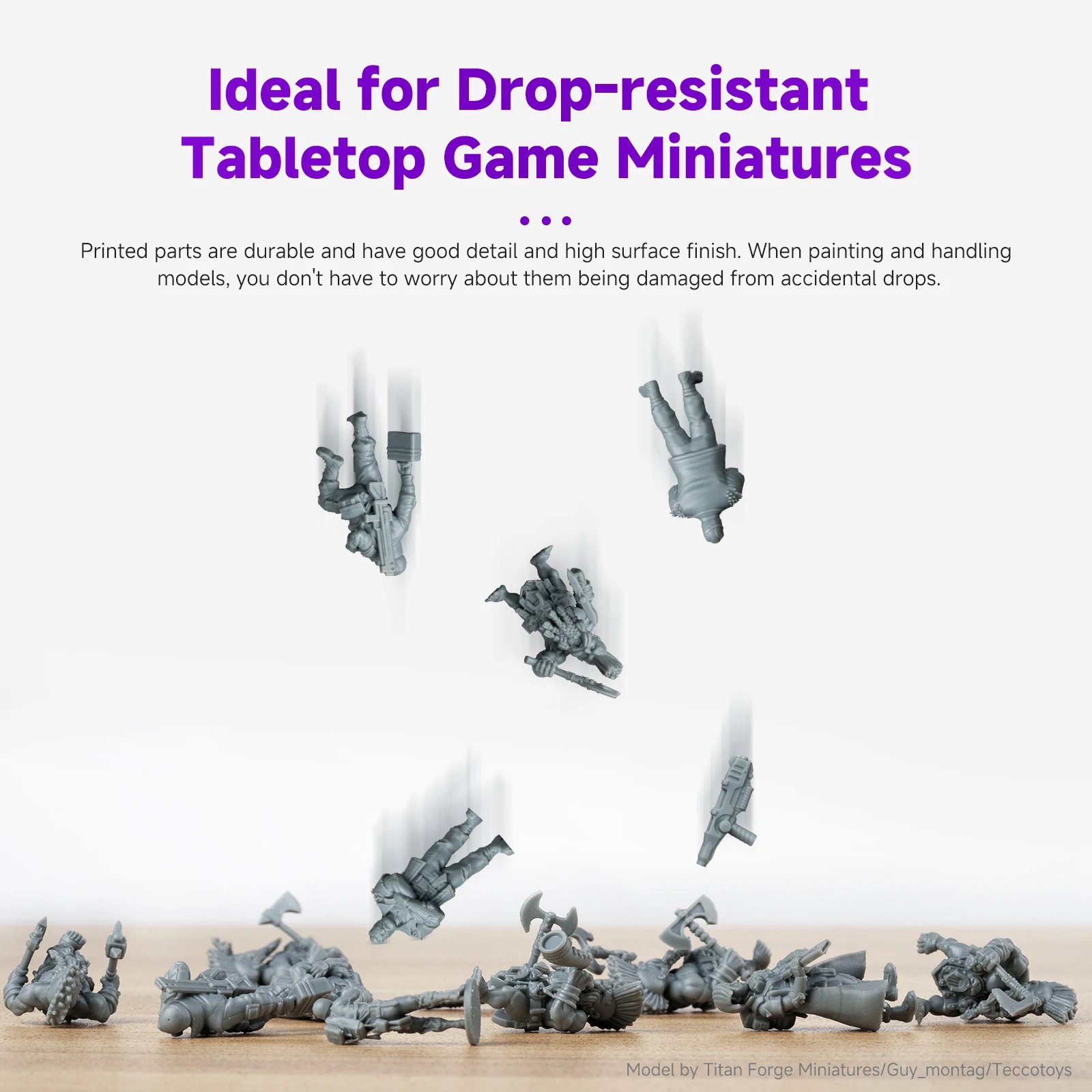

Ideal for Drop-resistant Tabletop Game Miniatures

Its durability, good detail, and high surface finish make Tough74 an ideal material for 3D printing tabletop game miniatures. When painting and handling models, you don’t have to worry about them being damaged from accidental drops, greatly enhancing the gaming experience. However, we recommend using a layer height of 0.05mm instead of 0.02-0.03mm for miniatures to avoid significantly increased printing difficulty.

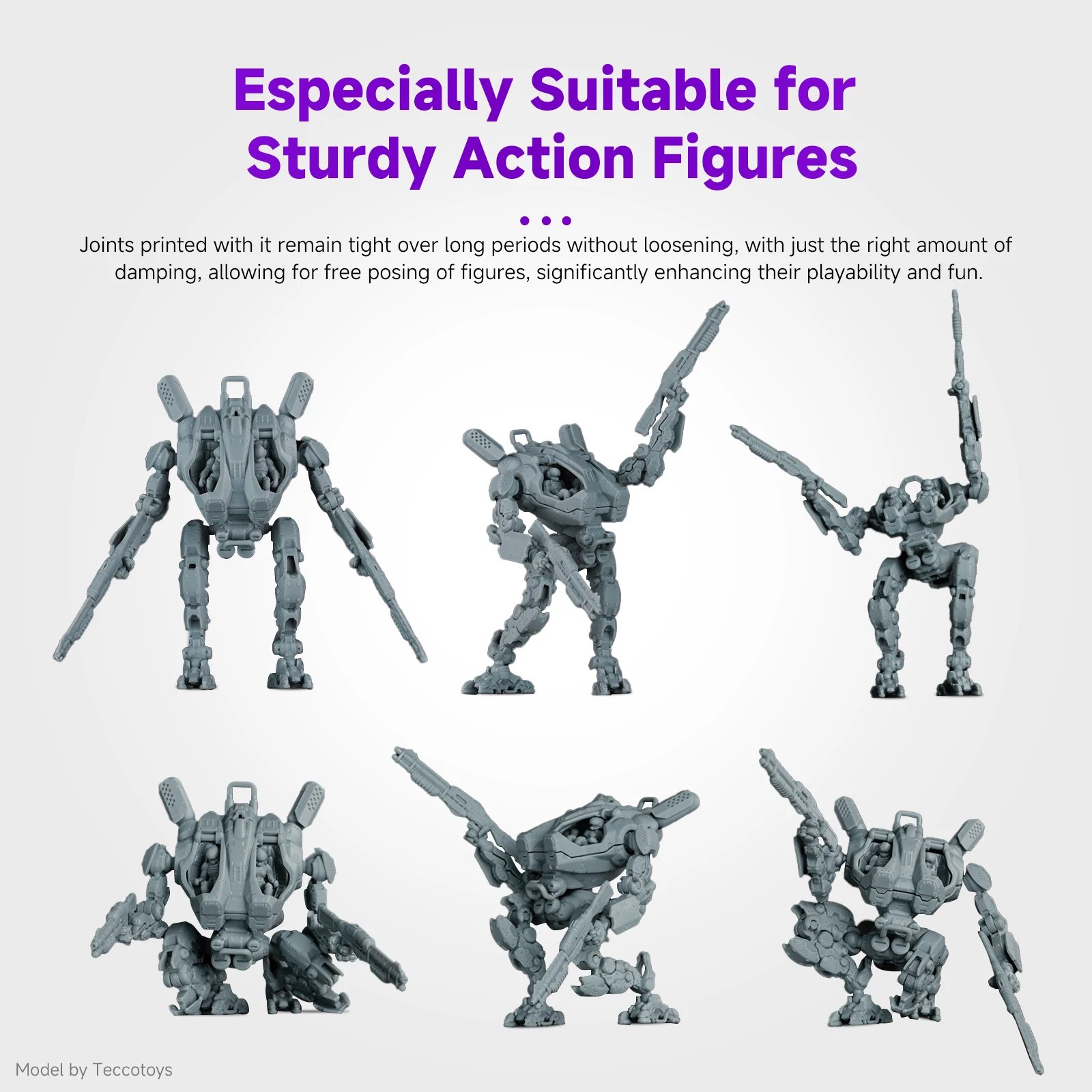

Especially Suitable for Sturdy Action Figures

The wear resistance, durability, and low shrinkage characteristics, along with excellent surface quality, make Tough74 an ideal material for manufacturing articulated figures. Joints printed with it remain tight over long periods without loosening, with just the right amount of damping, allowing for free posing of figures, significantly enhancing their playability and fun.

▌ Print Settings

Gray

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.05mm

Exposure Time: 2~3s

Bottom Exposure Time: 45~65s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥9mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s

Black

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.05mm

Exposure Time: 2.4~3.6s

Bottom Exposure Time: 55~75s

Lifting Height:

LCD Screen size less than 8.9 inches: 6mm

LCD Screen size ≥8.9 inches: ≥9mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s

▌ Cleaning and Post-curing

Cleaning method: move the handheld printed parts back and forth in the cleaning solution

Cleaning time: ≤5mins

Cleaning solvent: 95% Ethanol or IPA

Post-curing light source: 385-405nm UV(40W)

Post-curing time: 30mins

Tough74 V2, as a more advanced material compared to Tough74, offers improved precision, rigidity, and toughness. It is suitable for printing movable action figure prototypes, joints without thin walls or fine column structures, as well as industrial prototypes, enclosures, and parts that require short-term toughness and wear resistance.

▌ Descriptions

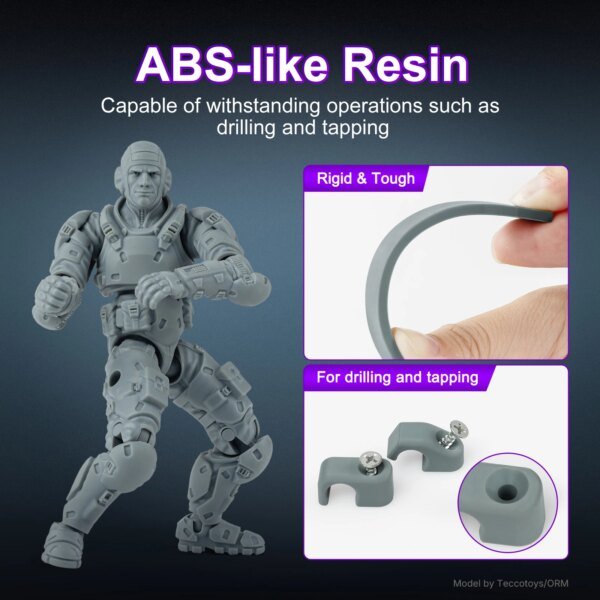

- ABS-like Resin

The mechanical properties of Tough74 V2 resin-printed parts are similar to those of tough thermoplastic materials, offering superior rigidity and toughness compared to Tough74 resin. It can withstand operations like drilling and tapping, allowing users to perform machining with confidence, without worrying about cracking or deformation

- Wear-Resistant & Scratch-Resistant

Tough74 V2 is a wear-resistant tough resin with high surface hardness. Printed parts can withstand daily friction, scratching, and other physical damage without easily generating powder during friction. It is suitable for printing action figure or joints without thin-wall or slender-column structures

- Smooth Surface

With an ultra-fine layer height of 0.03mm, stable forming is achieved, resulting in smooth and refined surfaces for printed parts that closely resemble the texture of traditional injection-molded parts. Minimal post-processing is required, significantly reducing finishing time and enabling you to complete your creations with greater efficiency

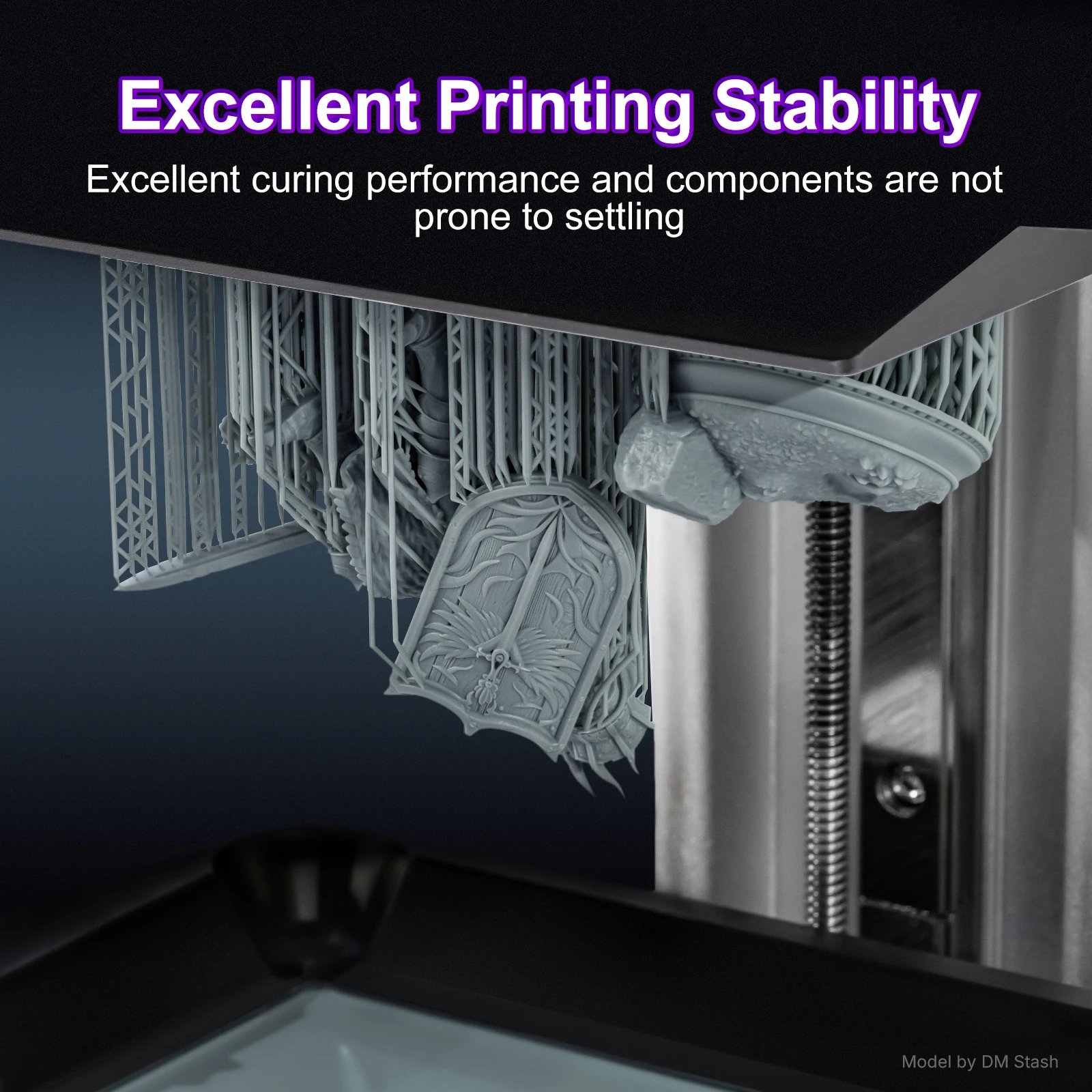

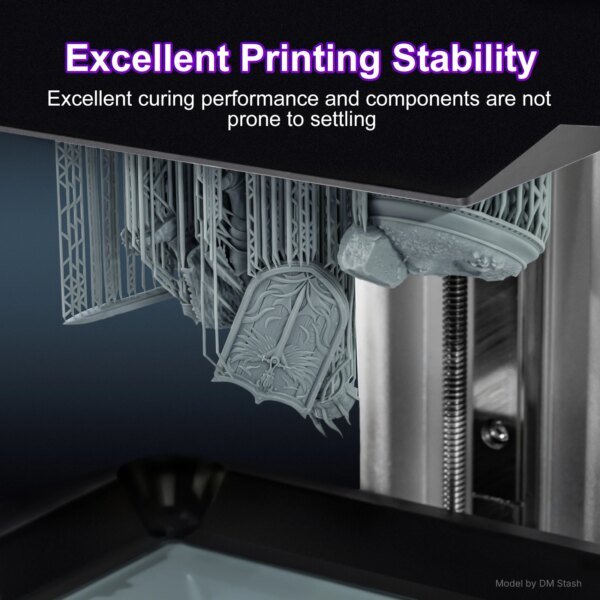

- Excellent Printing Stability

This resin combines rigidity and toughness with outstanding curing performance, making it resistant to stretching, deformation, or shifting during the 3D printing process, demonstrating exceptional stability. Additionally, the resin’s components are stable and not prone to sedimentation, reducing the need for manual stirring of the resin in the vat before each print, ensuring consistent quality with every print

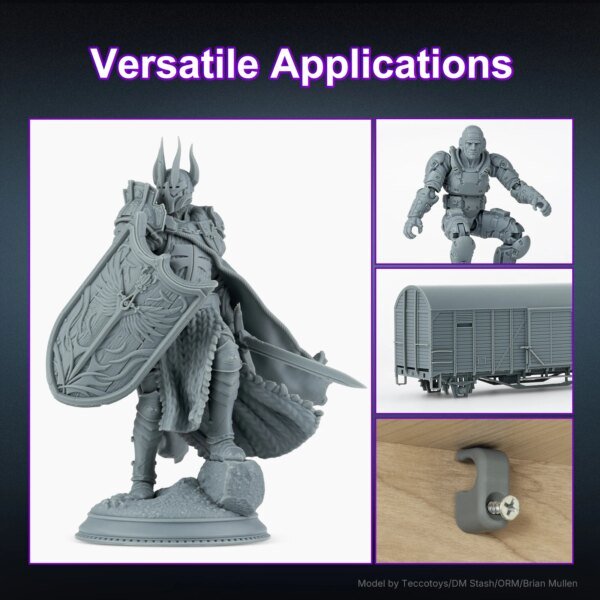

- High Precision, Versatile Applications

Tough74 V2 is a wear-resistant tough material. Compared to Tough74, offering enhanced precision, rigidity, and toughness. It is suitable for a wide range of 3D printing applications, including fine detailed action figure or joints without thin-wall or slender-column structures, as well as industrial prototypes, enclosures, and parts that require short-term toughness and wear resistance

Reviews

There are no reviews yet.